Introduction to Insect Orders

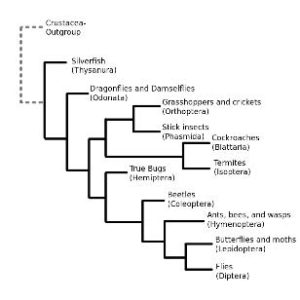

With more than 25 orders in the insect world, classifying one can be a daunting task, understanding how orders work can also be overwhelming. Order (Latin: ordo) is one of the eight major hierarchical taxonomic ranks in Linnaean taxonomy, the particular form of biological classification (taxonomy) set up by Carl Linnaeus in the 1700’s. Most common insects are included in one of eight major orders: Coleoptera (beetles), Lepidoptera (moths, butterflies), Hymenoptera (ants, wasps, bees), Diptera (flies, mosquitoes), Orthoptera (crickets, locusts), Odonata (dragon flies, damselflies), Homoptera (Aphids, Cicadas), and Hemiptera (Bugs, Backswimmers, Water Striders).

The representatives of an order are related based on the shape of their body, their legs, their mouthparts and especially their wings. The scientific name given to each of these orders usually ends with the suffix “ptera,” a Greek word that means wing. The first part of the name often indicates the shape, size, number or texture of wings.

This information is important in understanding their biology, behavior and in many cases, their control. Knowing the names of the different insect orders may not be as important as their individual identification, knowing the order may be important in their management.

Submitted by: Rich Gibson ACE, CFSQA

The Red Imported Fire Ant

Order: Hymenoptera Family: Formicidae Genus: Solenopsis Species: S. invicta

The red imported fire ant, also known as the fire ant, is a species of ant native to South America. In the United States, imported fire ants currently inhabit all or parts of Alabama, Arkansas, California, Florida, Georgia, Louisiana, Mississippi, New Mexico, North Carolina, Oklahoma, Puerto Rico, South Carolina, Tennessee, Texas, and Virginia. They are discovered sporadically in Kentucky, Missouri, and Maryland. The red imported fire ant has also been accidentally introduced to other countries. While not a common pest in commercial establishments, this ant may pose a safety concern to employees on facility grounds.

This small ant is red in color and has workers which range in size from small to medium, making them polymorphic. Workers measure between 2.4 and 6.0 mm. The head measures 0.66 to 1.41 mm, and is 0.65 to 1.43 mm wide. In the larger workers their heads measure 1.35 to 1.40 mm and 1.39 to 1.42 mm wide.

The lifespan of red imported fire ant workers depends on their size. Minor workers may live 30 to 60 days, media workers 60 to 90 days, major workers 90 to 180 days, and queens may live two to six years. Complete lifecycle from egg to adult takes between 22 and 38 days. The use of residual insecticides to treat ant mounds on a property is found to be the most effective method for eradication.

Submitted by: Rich Gibson, ACE, CFSQA

“We need Certified NOW!”

A longtime client and partner of both RKE and Comprehensive Food Safety (CFS) reached out seeking immediate assistance. This client was notified they must be certified to a Global Food Safety Initiative (GFSI) recognized audit scheme as soon as possible to satisfy a demand from one of their customers. CFS has always had a reputation in the industry for guiding a supplier through the certification process.

During initial meetings, the client stated they did not care which standard, only to be compliant within four to six months. It was decided the supplier would seek certification to the SQF standards as it would be most comprehensive to their operations.

The CFS team went to work writing the documented programs needed to attain certification while building records to support the implementation and certification process. Any GFSI implementation requires teamwork and cooperation between consultancy and client to make a seamless transition into the GFSI standards. CFS team members wrote procedures, trained personnel and were hands-on at the facility to ensure proper implementation and compliance. CFS conducted a mock audit, which was also used as a training exercise for the SQF Practitioner. Internal corrective actions were planned, implemented, and verified.

Within five months of contract and four months from the official project start date, the facility was certified to the SQF Food Safety Code: Manufacturing with an “Excellent” rating and only two minor non-conformances identified.

- Take away tips:

• It is sometimes best to utilize consultants who specialize in GFSI implementations rather than “trying it yourselves”

• Regardless of the project scope, it takes cooperation and teamwork to accomplish goals and objectives.

• Proper planning prevents poor performance.