Holiday Food Safety

It is that time of year again! People gathering to share large meals with plenty of leftovers. It is also the time of year for increased cases of foodborne illnesses. Do not let a case of “food poisoning” ruin your holidays by following these tips.

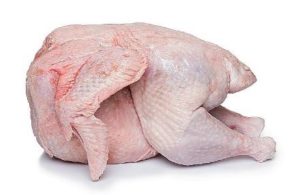

Separate: Keep raw meats, chicken, turkey, seafood, and eggs separate from all other foods, especially those which are ready to eat.

Cook food thoroughly: Meat, chicken, turkey, seafood, and eggs can carry germs that cause food poisoning. Use a food thermometer to ensure these foods have been cooked to a safe internal temperature.

Keep food out of the “danger zone”: Bacteria can grow rapidly in the danger zone between 40° F and 140° F. After food is prepared, keep hot food hot and cold food cold. Refrigerate or freeze any perishable food within 2 hours. The temperature in your refrigerator should be set at or below 40° F and the freezer at or below 0° F.

Of course, wash your hands frequently, do not eat raw dough or batter, and practice safe thawing methods. You need to remember to also reheat leftovers to the same temperature as if it were raw, this kills any harmful bacteria.

(More information available from the CDC Website)

Submitted by: Rich Gibson ACE, CFSQA

The Spider Beetle

Order: Coleoptera Superfamily: Bostrichoidea Family: Ptinidae Subfamily: Ptininae

The Spider Beetle is any member of about 500 species of insects sometimes considered a part of the family Anobiidae (order Coleoptera) and sometimes placed in their own family, Ptinidae. This reddish brown to black insect is very small in size from 1 to 5 mm with a globular body (like a spider), long thin legs, and no wings.

Spider beetles can be found throughout the world and are known to live in plant or animal remains, stored products, dry wood and museum specimens The white-marked spider beetle (Ptinus fur) and the shiny American spider beetle (Mezium americanum) are household (pantry) pests in North America.

Spider beetles will be found anywhere where food is not properly secured such as damaged bags or boxes or raw materials. They are not a common pest and usually will be brought into a facility through contaminated raw materials or other foods. The diet of the Spider beetle is grain based and would prefer to be in areas that contain grain products such as cereal, flour, or rice. Spider beetles are also known to infest old moldy products that contain moisture which provides an ideal environment to lay their eggs.

Control of Spider beetles follows the same integrated pest management methods beginning with sanitation, removal of contaminated materials, and residual treatments using crack and crevice applications of an appropriately labeled insecticide.

Submitted by: Rich Gibson, ACE, CFSQA

“Fowl” Odor

In the summer of 2021, a chicken & beef processor, who is a client of both RK Environmental Services (RKE) & Comprehensive Food Safety (CFS), received a complaint from the township regarding a rancid odor emanating from their facility. CFS was brought in to help with the root cause analysis, which would not have been necessary if a proper risk assessment had been conducted prior.

A couple of months into the new year, the facility switched from a dumpster to a compactor for their trash disposal. Due to the nature of operations, organic debris and juices clings to the discarded packaging material, creating a “meat trash marinade.” Since waste management is an essential part of operations, a risk assessment should have been conducted, especially when considering such variables as fluctuations in exterior temperatures, trash contents, seasonal increases/decreases in production/trash output, and a change in equipment design/capacity.

The first thing that was looked at is the frequency of trash pick-up. The previous dumpster was emptied when it was full (reactive). Considering that the compactor holds approximately four times more trash, pick-ups exceeded two weeks. As the summer temperatures began to rise, it wasn’t very long before the system deviation was evident. Fly activity developed quickly as did a rancid odor that the wind carried for miles.

The next element that was assessed was the equipment design and sanitation. Organic residue was accumulating in the seals and hard to reach areas under the hatch of the compactor. The dumpster was a different design, so the cleaning practices and frequency need to be adjusted accordingly. The exterior drain was also assessed, which was completely missed on the cleaning schedule, with no cleaning procedures in place.

The corrective and preventative actions implemented have remedied the issue to date. First, there is a daily deodorizing and rinsing of the compactor. On a weekly basis, the unit is being emptied, followed by a drain, pavement, and structural deep cleaning. Monitoring has been added to the daily and monthly self-inspections, with training provided to relevant personnel.

The primary purpose of a food safety management system is to manage the potential risk of product contamination… and a comprehensive risk assessment is the best tool there is for avoiding those unnecessary system deviations/failures.

“Fowl” Odor

Submitted by: Todd Kaback

Sr. Food Safety Consultant

Comprehensive Food Safety