Understanding Rodenticide Types

According to the Environmental Protection Agency (EPA), there are three types of rodenticides in use today:

According to the Environmental Protection Agency (EPA), there are three types of rodenticides in use today:

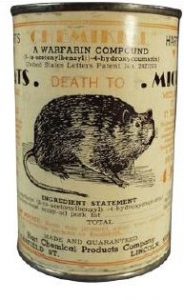

First-generation anticoagulants include the anticoagulants that were developed as rodenticides before 1970. These compounds are much more toxic when feeding occurs on several successive days rather than on one day only. Chlorpophacinone, diphacinone and warfarin are first-generation anticoagulants that are registered to control rats and mice in the United States.

Second-generation anticoagulants were developed beginning in the 1970’s to control rodents that are resistant to first-generation anticoagulants. Second-generation anticoagulants also are more likely than first-generation anticoagulants to be able to kill after a single night’s feeding. These compounds kill over a similar course of time but tend to remain in animal tissues longer than do first-generation ones. These properties mean that second-generation products pose greater risks to non-target species that might feed on bait only once or that might feed upon animals that have eaten the bait. Due to these risks, second-generation anticoagulant rodenticides no longer are registered for use in products geared toward consumers and are registered only for the commercial pest control and structural pest control markets. Second-generation anticoagulants registered in the United States include brodifacoum, bromadiolone, difenacoum, and difethialone

(Source material: http://www2.epa.gov/rodenticides/restrictions-rodenticide-products)

Submitted by: Rich Gibson, CHA, ACE

The Dark Eyed Fruit Fly

Order: Diptera Family: Drosophilidae Genus: Drosophila Species: D. repleta

Like many filth flies, the dark eyed fruit fly is very small, about 1/8-inch-long, and with dark brown to black bodies and very dark colored eyes. Lighter colored spots over the thorax create a “freckled” appearance. They are slightly larger than the common “vinegar” flies with red eyes. The light-colored larva is legless and very small and tapers to narrower ends at both front and back of the body. The pupa is distinctive with a pair of “horns” pointing forward at the anterior end.

Cleaning is vital to control of these flies. An inspection is needed to identify the unsanitary condition that provides the food resource for the larvae and removal of the organic material will remove larvae and prevent repeat infestation. Flooring and other materials in poor condition need to be repaired. The use of biological cleaners can remove organic buildup in drains and other places. The inspection must include all food service and preparation equipment in restaurants, including drink dispensers, salad bars, and other equipment where moisture is present and may be trapped in tubes, gaps, or holes. (pestweb)

Submitted by: Rich Gibson, CHA, ACE

Flies in the House

A snack food manufacturer had noticed an increasing number of flying insects near the nut roasters. RK Environmental Services (RKE) Regional Operations Manager was contacted and a Service Specialist dispatched to investigate.

A snack food manufacturer had noticed an increasing number of flying insects near the nut roasters. RK Environmental Services (RKE) Regional Operations Manager was contacted and a Service Specialist dispatched to investigate.

The Service Specialist was familiar with the location but had never noticed any flying insects during past services or inspections. So, an investigation was completed with the help of the plant Sanitation Supervisor, in addition to a review of archived service and trend reports.

During the inspection of Roaster 1 and 2 adult dark-eyed fruit flies where found resting on adjacent walls. The proper identification of this insect was critical in developing an action plan. Understanding that the larvae will feed in very wet areas with a buildup of organic sludge as well as in fermenting fruit and vegetable materials helped in determining the source of infestation. The Specialist turned his focus to any place water can settle and allow buildup of organic matter and provide food resources, including floor drains, under and around broken tiles and loose flooring, along edges of floors, etc.

Below the roaster’s, floor drains collect wastewater and allow organic material and water to accumulate. Additionally, cracks have developed in the floor around the drain basin further allowing excessive organic build-up.

Improved cleaning is vital to control these flies, was discussed and added to the Master Sanitation Schedule. Also, instruction on repairing the floor and other materials in poor condition was reviewed with the client. A biological cleaner was used to remove organic buildup in drains and other places. The use of pyrethrum was avoided due to the facility being operational at the time.

- Take Away Tips:

- Insect identification is critical

- There is no substitute for a thorough inspection

- Effective sanitation is key to an IPM program