Culture Shift

We covered food safety culture in previous editions of this technical bulletin and the topic is still a hot one. With the Global Food Safety Initiative (GFSI) pressing audit schemes to include requirements focused on building a culture of food safety within their organizations, it is time to discuss again. The “we’ll fix it for the audit” and “don’t worry, it won’t be there for the audit” mentality should no longer exist. Food manufacturers need to empower their employees to speak up and ask questions related to food safety.

We covered food safety culture in previous editions of this technical bulletin and the topic is still a hot one. With the Global Food Safety Initiative (GFSI) pressing audit schemes to include requirements focused on building a culture of food safety within their organizations, it is time to discuss again. The “we’ll fix it for the audit” and “don’t worry, it won’t be there for the audit” mentality should no longer exist. Food manufacturers need to empower their employees to speak up and ask questions related to food safety.

The culture shift can be slow but can be accomplished. Simple tasks by management such as Management by

Wandering Around (MBWA), a method employed by many top tier organizations. This method allows managers to

keep their fingers on the pulse of their organization while making their presence known. Communication is essential in

building a culture around food safety. Many Quality Assurance Managers spend hours trending and analyzing

consumer/customer complaint data, internal audit results, and laboratory results but file it away for their audits and

never share that information. Whether the information is good or bad, it needs to be shared. Setting up a Food Safety

& Quality Assurance bulletin board in an employee breakroom is an excellent start. Frontline employees cannot

improve if they do not know how they are performing. Share objectives, their results, and celebrate the wins. Action

plan shortcomings and foster a culture of food safety while continually improving.

Submitted by: Rich Gibson, ACE, CFSQA

The Hairy Fungus Beetle

Order: Coleoptera Family: Mycetophagidae Genus: Typhaea Species: T. stercorea

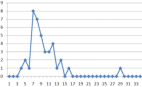

Adult Hairy Fungus Beetles (T. stercorea) are about 3 mm (0.12 in) long, brown, oval, flattened, and have hairy elytra with parallel lines of fine hairs. The larvae are able to move easily and the adults can run very fast and fly. Hairy fungus beetles may be found indoors or outdoors in places where grains or other food products are stored under conditions favorable for mold to grow. This insect serves as an indicator that grains or other foods are too damp for safe storage and may be going out of condition. Adults may fly or crawl into railcars or food processing plants from moist moldy residues nearby. This species of beetle occurs on a wide variety of foodstuffs, including grains and cereal products. It is a scavenger that feeds primarily on molds.

The hairy fungus beetle does not damage stored grain. Its presence in a bin indicates mold growth on the grain or

introduction of moldy field corn during harvest. Well managed grain is typically not infested with the hairy fungus beetle. Control of this insect begins with good management. Before new grain is placed in a bin, the old grain should be thoroughly removed from the walls, floors, and augers inside the bin. Chemical options for control are available and should be considered as a last resort. Proper implementation of IPM practices will often solve the infestation concerns.

Submitted by: Rich Gibson, ACE, CFSQA

Bird and Wildlife Exclusion Program

A large food manufacturing facility, and RKE client, was experiencing pressure from Sparrows in their exterior food waste compactor area. RKE was asked to provide solutions to this issue as the birds were attracted to the compactor area by spillage on the ground but then occasionally, they would also enter the facility. Birds within a food plant poses significant contamination hazards to products and surfaces through their droppings and shed feathers.

RKE’s bird management division performed a detailed analysis of the target areas worked closely with the client to develop a bird management program that consisted of:

• Audio Deterrents

• Visual Deterrents

• Multi-Sensory Deterrents

• Increased Sanitation

The techniques noted above were temporarily successful, but after a period of time the birds were no longer deterred, or the attraction of the available food was too strong, and the birds returned to the area. At this juncture physical exclusion was implemented in the form of bird netting. The challenge to the installation of bird netting in this bay was the client needed it to be opened and closed easily to facilitate movement of workers. RKE designed the netting in large panels to move back and forth horizontally from the ceiling to the ground like a shower curtain and this proved successful to exclude the sparrows. This was not to be the end of the issues, enter another challenge, Squirrels.

Due to the completion of adjacent housing project the area squirrel population had become displaced causing them to seek out new harborages and food sources, they found both in the farmers waste compactor area. The squirrels foraged on spillage and created nests in overhead transformer units posing risks of shortages and hazards to workers.

RKE observed the squirrels gnawing holes in the bird netting, which was a nylon type material to gain entry, so we

decided to replace the nylon with chicken wire type netting panels which the squirrels could not gnaw through. This

approach combined with trapping and relocation was effective at mitigating the squirrel pressure.

Take Away Tips to successful bird/wildlife mitigation.

Perform detailed inspections of the target areas to identify environmental, physical, and personal practices that may

impact successful control:

• Understand the target pest.

• Involve your client in the process.

• Think creatively, the solution may require utilizing a combination of techniques.