The Cigarette Beetle

Order: Coleoptera Family: Anobiidae Genus: Lasioderma Species: serrricorne

The Cigarette Beetle (CB) is a Stored Product Pest, which gets it’s name from attacking tobacco wherever it is stored. It is distributed throughout tropical regions but can be found worldwide. Especially, wherever dried tobacco in the form of leaves, cigars, cigarettes, or chewing tobacco is stored.

The Cigarette Beetle (CB) is a Stored Product Pest, which gets it’s name from attacking tobacco wherever it is stored. It is distributed throughout tropical regions but can be found worldwide. Especially, wherever dried tobacco in the form of leaves, cigars, cigarettes, or chewing tobacco is stored.

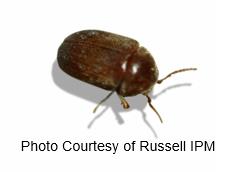

Adult CB are quite small, approximately 2 – 3 mm (about an 1/8 of an inch), and are reddish brown in color. The appearance of the insect is long and oval and the head is often concealed by the pronotum (plate covering the first region of the thorax) when the specimen is viewed from above. The wing covers known as elytra are covered with fine hairs. If disturbed, they will often pull in their legs, tuck their head and remain motionless. CB prefer to harbor in dark/dimly lit cracks & crevices but become active and fly readily in bright, open areas.

Mature larva are about 1/16 – 1/8” ( 2 – 3mm) long and C-shaped. Their coloring is white containing many long hairs. Appearance is very similar to that of the Drugstore Beetle.

Females can lay 30 – 42 oval, whitish eggs in and about food materials. The eggs will hatch in 6 – 10 days during warmer temperature. Larval instars are 4 – 6. Full-grown larva will pupate in silk like cocoons covered with bits of food and debris. The life cycle, which is complete metamorphosis requires 30 – 90 days with 3 – 6 overlapping generations per year. Adult CB may live from 23 – 28 days and are known for being very strong fliers.

Cigarette Beetles are considered the most damaging pest of stored tobacco. However, it is a major pest of many stored food products including flours, dry mixes, dried fruits such as dates/raisins, cereals, cocoa, coffee beans, herbs, spices, nuts, rice as well as dry dog food. Non-food products include dried plants, herbarium specimens, potpourri & furniture stuffing to name a few. Larval feeding causes direct damage to food and non-food items. Defiled product contamination will occur by the presence of beetles, larvae, cocoons, frass (fecal matter), and insect parts. Indirect damage will occur when CB are chewing through corrugate, containers & packaging. CB are known as external feeders. Commercially, they are often found in bakeries, mills, pet food & cereal manufacturing facilities, snack food plants, confectionaries, distribution centers as well as in retail stores.

The first step for control & elimination of the CB is proper identification. This can be achieved by implementing the use of Pheromone Monitor Traps (PT) as part of the overall Integrated Pest Management (IPM) program. Inspection of affected product(s) is next. Reviewing cleaning, receiving and storage practices independently as well as with the client is important. The use of residual insecticides, which are labeled for CB can be applied by a licensed applicator to cracks & crevices. IGR’s, (Insect Growth Regulator) which disrupt how insects grow & reproduce can also be utilized as part of the IPM program.

Upon finding an infestation or evidence of this insect, stored or incoming product should be immediately isolated. In the case where product(s) are being received by a vendor, infested product should be rejected. Ideally, damaged product should be destroyed. Proper storage practices utilizing FIFO (first in first out) should be practiced at all times. Ongoing cleaning is necessary and vacuuming of cracks & crevices should also be implemented. To gain rapid control in the event of an emergency, a Space Treatment can be performed with the use of a non-residual insecticide for quick knockdown. Fumigation, which is the treatment for controlling and eradicating a pest problem with the use of an approved gas material known as a fumigant can also be utilized. This would apply for large scale infestations. The aforementioned treatments should always be performed by licensed applicators. The “Best Practice” is to follow standard control procedures for Store Product Pests when dealing with the CB.

Submitted by: Joe Romito, ACE

German Cockroach Infestation

The Regional Operations Manager (ROM) of the Central Region was asked to assist in a difficult Cockroach infestation at one of the larger RKE clients in the area.

Upon arrival a thorough inspection of both lines was completed to assess the facility and the affected areas. During the inspection, heavy activity was found in electrical panels. The panels were unlocked, deenergized, and locked out by the site electrician. The boxes were vacuumed to remove any visible cockroach evidence. An insecticidal bait labeled for control for cockroaches and for application in a food establishment was applied for continued control.

The initial clean out yielded great results with hundreds of cockroaches being cleaned out. Over the next few weeks, the site staff would continue to get a “stray cockroach” sighting in the area. Based on the reported sightings, RKE expanded the inspections to include adjacent areas. The area above the production lines had a roof hatch that, when opened, RKE observed a damaged rubber seal. The rubber seal was harboring hundreds of German Cockroaches that would fall from the hatch to the mixer below. The hatch was vacuumed to remove remaining activity and the seal was replaced by the site maintenance team. The site has been Cockroach free since the last finding.

Take Away Tips:

• Look all around you including areas you would not usually find activity.

• Activity can be found in areas you would least expect.

• Tools to use include:

-A powerful flashlight

-Inspection mirrors to see inside hard to reach areas

-Screwdrivers to pull back wall panels

-Vacuums to remove as many cockroaches as possible

-Needle nose pliers to gently lift flooring and carpets for applications.

Submitted by: Will Krough