Introduction to Phosphine as a Fumigant

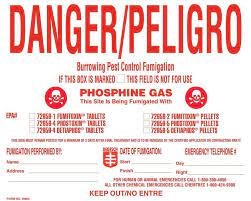

Phosphine is a colorless, flammable, highly toxic compound most often used in fumigation. Phosphine fumigants are sold in solid form, either as aluminum phosphide or magnesium phosphide. When these solid fumigants are exposed to water vapor in the air, a chemical reaction occurs releasing phosphine gas (hydrogen phosphide) and heat. The breakdown of the solid fumigant starts slowly, gradually accelerates, and then tapers off. When the chemical reaction has finished, all that is left is a non- hazardous gray powder consisting of aluminum hydroxide and other inert materials. Phosphine gas is highly toxic, reactive, and potentially explosive. Because of the dangers associated with their use, phosphine fumigants are restricted-use pesticides that can be used only by trained and certified applicators in accordance with label instructions. Farmers who have a private applicator’s license can apply phosphine fumigants on their farms.

An effective fumigation requires that the phosphine gas be held in the infested structure long enough to kill the target pests. After fumigation, the gas must be vented to the legal level for human exposure. These requirements are constant regardless of the structure involved; however, different types of structures may require different application procedures and safety considerations.

(Some information sourced from the National Agriculture Database)

Submitted by: Rich Gibson, ACE, QFSQA

The Brown Marmorated Stink Bug

Order: Hemiptera Family: Pentatomidae Genus: Halyomorpha Species: H. halys

The Brown Marmorated Stink Bug is often referred to simply as a Stink Bug. As part of the order Hemiptera, the stink bug is a “true bug.” Stink bugs are approximately 1.7 cm long and about as wide, forming the heraldic shield shape characteristic of bugs in the superfamily Pentatomoidea. The name “stink bug” refers to the scent glands located on the dorsal surface of the abdomen and the underside of the thorax. This species probably has a single generation per year in Pennsylvania, although warm spring and summer conditions may permit the development of two generations. Adults emerge in the spring (late April to mid-May) and mate and deposit eggs from May through August. The eggs hatch into small black and red nymphs that go through five molts. Adults begin to search for overwintering sites starting in September through October.

Although this insect is not a food infesting pest within a food plant or distribution center, it is a serious pest of fruit, vegetable, and other crops. It is an occasional invader of buildings which may end up in a facility and needs to be removed.

Mechanical exclusion is the best method to keep stink bugs from entering buildings. Cracks around windows, doors, utility pipes, behind chimneys, and underneath the wood fascia and other openings should be sealed with good quality silicone or silicone-latex caulk. Damaged screens on doors and windows should be repaired or replaced. Chemical control methods are often not effective.

Submitted by: Rich Gibson, ACE, QFSQA

Retail Mouse Infestation

Recently, one of RK Environmental Services’ (RKE) multi-location supermarket clients had an increase in mouse activity, primarily in the bread department. A detailed assessment of the IPM program was performed, key areas of potential entry / harborage identified, and a corrective action plan proposed. The corrective action plan called for a commercial intensive service to seal potential entry points and an aggressive trapping program. The commercial intensive treatment was performed, three mice were caught however the store staff reported ongoing damage to a specific bread on a nightly basis. This was alarming as the structural issues that could allow rodent entry had been corrected. Additionally, zero mice were being caught, there were no droppings in the problem area and there were no harborage opportunities. The store staff were also packing away the bread at closing each night.

Recently, one of RK Environmental Services’ (RKE) multi-location supermarket clients had an increase in mouse activity, primarily in the bread department. A detailed assessment of the IPM program was performed, key areas of potential entry / harborage identified, and a corrective action plan proposed. The corrective action plan called for a commercial intensive service to seal potential entry points and an aggressive trapping program. The commercial intensive treatment was performed, three mice were caught however the store staff reported ongoing damage to a specific bread on a nightly basis. This was alarming as the structural issues that could allow rodent entry had been corrected. Additionally, zero mice were being caught, there were no droppings in the problem area and there were no harborage opportunities. The store staff were also packing away the bread at closing each night.

Follow Up Inspections – A follow up inspection of the facility was performed focusing again on the bread storage racks, as well as checking for new structural and sanitation opportunities. During this visit, we again asked the area staff if they’d seen any signs of mice were told only at the bread.

New Info – After performing the follow up inspection of the store I called the owner to debrief. He shared that he’d also been looking into the mice activity and learned new information regarding the bread.

The store in question is located in a congested urban area and does not have any private loading/receiving area. The specific bread product that was having rodent damage was usually delivered to the store location in the early morning, prior to the store being open. The bread usually spent one to two hours on the sidewalk prior to being received into the store. This new bit of information revealed the rodent damage was occurring while product was outside of the store.

Corrective Action – Store staff changed delivery times to allow for delivery directly into the store.

Take Away Tips:

- No one point of contact may have all the details regarding pest activity so interviewing area workers may provide key details on pest sightings.

- If the area of the sighting has minimal or no potential for the target pest to harbor it may be an issue of pests being transferred, transported or damage may be occurring elsewhere.

Submitted by: Ricardo John, ACE

Regional Operations Manager

RK Environmental Services