Environmental Monitoring

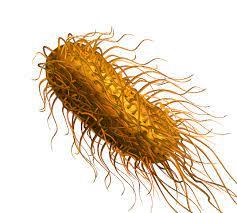

Every year there are hundreds of food recalls in the United States. While many are made in an abundance of caution, even more are initiated through confirmed lapses in food safety or due to biological contamination from pathogens. The pathogens of concern are Salmonella, Listeria Monocytogenes, and E. Coli. To reduce the risk of product contamination and subsequent recall, food manufacturing facilities will develop, document and implement Environmental Monitoring Programs (EMP).

An EMP is a sampling and testing process to evaluate a facility’s overall environment for pathogens, spoilage and indicator organisms, and, in some cases allergens. The EMP is a risk-based program that allows a manufacturer to determine if there is a hazard present in the facility that may end up in the food and eventually on the dinner table of a consumer.

A sound EMP will be strategic and encourage a “hunting down” methodology to look in all cracks, crevices, and areas of concern instead of superficial sampling of already cleaned and sanitized areas. Using a zone approach, an EMP will look at the environment which will include floors, walls, drains, door handles, forklift wheels, and equipment (non-food contact). A zone approach typically utilizes four zones, with zone one being a food contact surface such as a conveyor, mixer, or utensil. With Zones 2-4 away from food contact surfaces. Using the zone approach allows a manufacturer to truly test the environment for pathogens to determine if there is risk to food contact surfaces or the food itself.

Identifying the presence of a pathogen on a floor is a crucial step in keeping it out of the food. When a pathogen is confirmed in zone 2, for example, the next sampling areas may be zones 1 and 3. As sampling zones are expanded one can determine if the pathogen is “spreading” or that it may have been just a one-time concern. An EMP is your early warning system and should be meticulously managed.

Often times regulators such as the FDA or USDA will swab and sample hundreds of locations in a facility to determine risk and compliance. It is always a good idea to duplicate the samples to get your own baseline to work from. When regulators find positive results for pathogens of concern it may result in a “forced” recall, a work stoppage or suspension. Being a few steps ahead is always ideal.

Submitted by: Rich Gibson, ACE, CFSQA

The Phorid Fly

Order: Diptera Family: Phoridae Genus: Megaselia Species: scalaris

Phoridae are a family of small, humpbacked flies; which resemble Fruit Flies. The common name of humpbacked fly comes from their humpbacked profile when viewed from the side, which is due to their small head as well as prominent pronotum. The pronotum is the dorsal plate of an insect’s prothorax, which is the anterior segment of the thorax of the insect that also does not bear wings. Phorid Flies are considered a nuisance pest. There are approximately 226 species, which are recognized within the United Sates & Canada. Worldwide, there are over 2,500 species.

Adult Phorid Flies are approximately 1/64” – 1/4” long with a characteristic humpbacked appearance in lateral view. The common coloring of the insect is black, brown or yellowish. Antenna is very short basal two segments & very small. The 3rd segment is globular bearing a long arista (bristle). The wings of the insect contain heavily pigmented veins in the front (costal), remaining veins of 3 or 4 in the oblique area. The hind femur is also flattened. Phorid Flies go through complete metamorphosis (egg, larva, papal & adult). Female insects lay their eggs on or in as well as close to larval food. It is common for 1 -100 eggs to be laid at one time and a female will lay just under 800 eggs during her lifetime. There are 3 larval instars, which the 3rd instar larva crawls to drier areas to pupate.

Adult insects are commonly found on larval food materials, which consist of decaying organic matter such as dung; vertebrate & invertebrate carrion (decaying flesh) & fungi. They can also be found around flowers and plants due to decaying plant material. The locations of where these insects are found are usually unsanitary. As a result, they have the ability to transport various disease-causing organisms to food materials. Within structures, breeding materials can include moist organic matter lined within drain pipes; base of trash receptacles; elevator pits; refuse disposals; cracks & crevices commonly found in kitchens. Additionally, they can also be found in mop heads, septic systems as well as in rotting meat & vegetables. Overwatered soil for flowers and plants can be indicative of these insects as well. Various species of this insect such as the Coffin Fly can also be found in morgues, mortuaries and mausoleums.

To mitigate risk, a 5-step approach can be utilized, which consist of identification; inspection; sanitation; mechanical control/exclusion & insecticide applications when necessary. Finding and eliminating all breeding site(s) is essential for total control. In addition to a comprehensive Integrated Pest Management (IPM) program, Insect Light Traps (ILT) can be utilized for the monitoring of adult insects as well as thresholds. Approved bio-enzyme and microbial products can be utilized to treat the biofilm, which builds up in drains and floors. Bleach is not considered a best practice, as it does not eliminate the larvae breeding within biofilm. Leaking, damaged/broken pipes and sewage lines contributing to Phorid Flies should be repaired or replaced for total control & elimination. Residual insecticides are seldom needed but ULV application with non-residual insecticides can be used to effectively eliminate adult insects. The implementation of eco-friendly products such as Green Drains when applicable can also be utilized within drains to allow water and debris to flow freely while blocking pests, odors & gases. Therefore, assisting with the prevention of Phorid Flies.

Submitted by: Joe Romito, ACE, Comprehensive Food Safety

RKE Technical Bulletin – February 2023

Specializing in pest management & food safety consulting for food processing plants

Home » RKE Technical Bulletin – February 2023