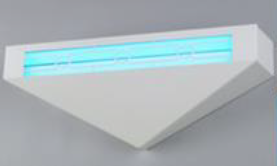

Insect Light Traps

Insect light traps (ILTs) can effectively control flying insects in many locations, but only if they are maintained properly. A typical maintenance program includes cleaning and inspection, glue board replacement, and lamp replacement. Over time, the ILT lamps (bulbs) lose their UV efficiency with a typical bulb losing 20 percent of its efficiency in just the first four days. Output continues to drop at a decreasing rate to 60 percent in less than three months and after 8,000 hours of use, the UV light (which we can’t see) is no longer attractive to flying insects.

Most manufacturers recommend that lamps be replaced at least annually. The effective life of a lamp is about 7,000 hours or 9½ months of use. Even if the light looks OK, it may no longer attract insects. Get in the habit of replacing the lamp each spring so that your insect light traps are working at peak when you most need them. (PCT Online) Light trap bulbs contain mercury and must be managed as hazardous waste according to EPA. Although EPA would like pest control companies to handle their bulbs as hazardous waste, it has relaxed the regulations to allow businesses to dispose of bulbs as “universal waste.” Used ILT bulbs can be disposed of in sanitary landfills unless you are disposing of large quantities.

Submitted by: Rich Gibson, CHA, ACE

The Fruit Fly

Order: Diptera Family: Drosophilidae Genus: Drosophila Species: Drosophila

The Fruit fly (AKA the Vinegar Fly) is a small fly only 1/8 to 1/6 of an inch in size. Big red eyes typically. Yellow to gold body. The fly goes through complete metamorphosis meaning egg, 3-4 larval instars, pupae, adult. Adults will lay eggs in areas of poor sanitation. This can consist of over ripened fruit, bottom of drink bottles with a small amount of liquid left, dirty drains, and even in the bristles of wet mops. The whole life cycle can happen in just about a week. While fogs and sprays can knock back adults it is more effective to control against where the flies breed. 16-gauge mesh or finer screening may exclude adults from entering.

The main ways of control are limiting food and dirty containers. Cleaning drains and other areas where water can accumulate. Trashcans without liners or lids that are not cleaned regularly are also good locations for breeding. Fruit flies have not been known to carry pathogens effectively and so do not pose a risk of disease transmission secondarily. The only concern is that due to high population growth adults may end up in machinery or product and pose a contamination risk.

Submitted by: Rich Gibson, CHA, ACE

Rodent Excreta

During an inspection of a small ingredient manufacturing facility thousands of mouse droppings were found littering the floor of an often-unused maintenance shop. The facility did not have a full-time, dedicated maintenance team so the shop was rarely used and had the lights off for extended periods of time. As the Comprehensive Food Safety team member approached the door, a distinct animal odor was noted, a clear indicator of rodent activity in the immediate area. Entering the shop there was a clear crunching sound as the inspection team walked onto mouse droppings. This, of course, is a major red flag in any facility, especially a food handling facility.

The team inspected the area and found no evidence of active mouse nests, signifying the mice were coming and going or the droppings were simply old and have been there for a long time. The inspection team noted the shop was along an exterior wall and there were no rodent control devices present. When asking the facility manager if they had a contract service provider for integrated pest management (IPM), he indicated they “had a guy come out once in a while”, another red flag.

The accumulation of feces from mice (and rats) can spread bacteria, contaminate food sources and trigger allergic reactions in humans. Once the fecal matter becomes dry, it can be hazardous to those who breathe it in. Most importantly the droppings can spread diseases and viruses, including Hantavirus, Bubonic Plague, Salmonellosis and Rat-Bite Fever.

RK Environmental Services was contracted soon after and has been providing service since. Upon initial service, the droppings were cleaned using a filtered vacuum, area was sanitized using a chlorinated cleaner and a formal IPM program designed specifically for their operation. Snap traps were installed throughout the facility to get an initial “knock down” of rodent pressure and mechanical rodent control devices installed and are inspected weekly. After a month, the facility was rodent free.

- Take Away Tips

- All areas should be inspected frequently

- An IPM program is essential to operations

- Not all IPM Programs are created equal

Submitted by: Rich Gibson, CHA, ACE

RKE Technical Bulletin – February 2020

Specializing in pest management & food safety consulting for food processing plants

Home » RKE Technical Bulletin – February 2020